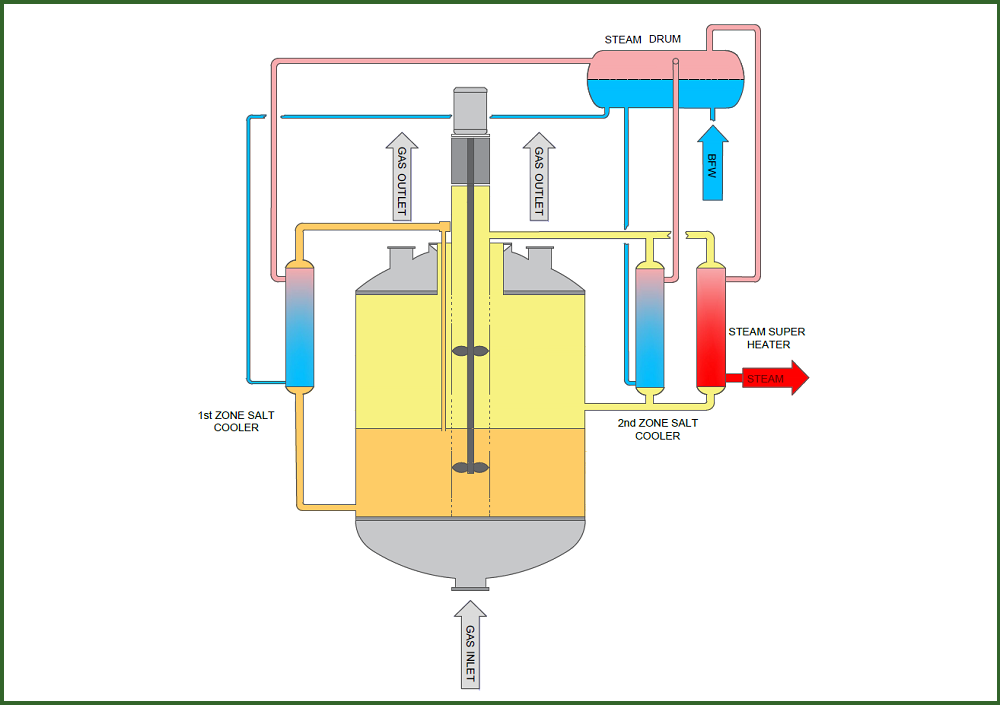

The Research and Development Team from Technobell’s Technology department has successfully finished the design of its new high capacity Double Zone Reactor for n-butane based Maleic Anhydride production with single train capacity up to 60,000 TPY.

The most advanced reactor is a result of constant research and development of Technobell’s engineering team, well-known for its continuous focusing on technology know-how and process equipment improvements based on market demands and known bottlenecks of worldwide operating reactors.

The new reactor combines the advantage of the revolutionary performance of Technobell’s licensed Double Zone Reactor and high production capacity resulting in a market leading production performance, productivity, economisation and efficiency.

Reactor’s key features:

- Concentric salt circulation results equal salt distribution both in radial and axial directions around the catalyst tubes.

- Central reaction gas inlet with special gas distributor design ensures identical GHSV in each catalyst tube.

- Operation with the Double Zone Reactor leads to high production flexibility with exceptional high reaction maleic anhydride yield.

- Gives flexibility to the end-user to generate any MP, HP or HHP steam as required by its process.

- Operation with high n-butane concentration in the feed gas parallel with high n-C4 conversion and selectivity.

- Reduced hot-spot temperature and smooth catalyst temperature profile extends the catalyst lifecycle.

- Significant investment cost reduction.