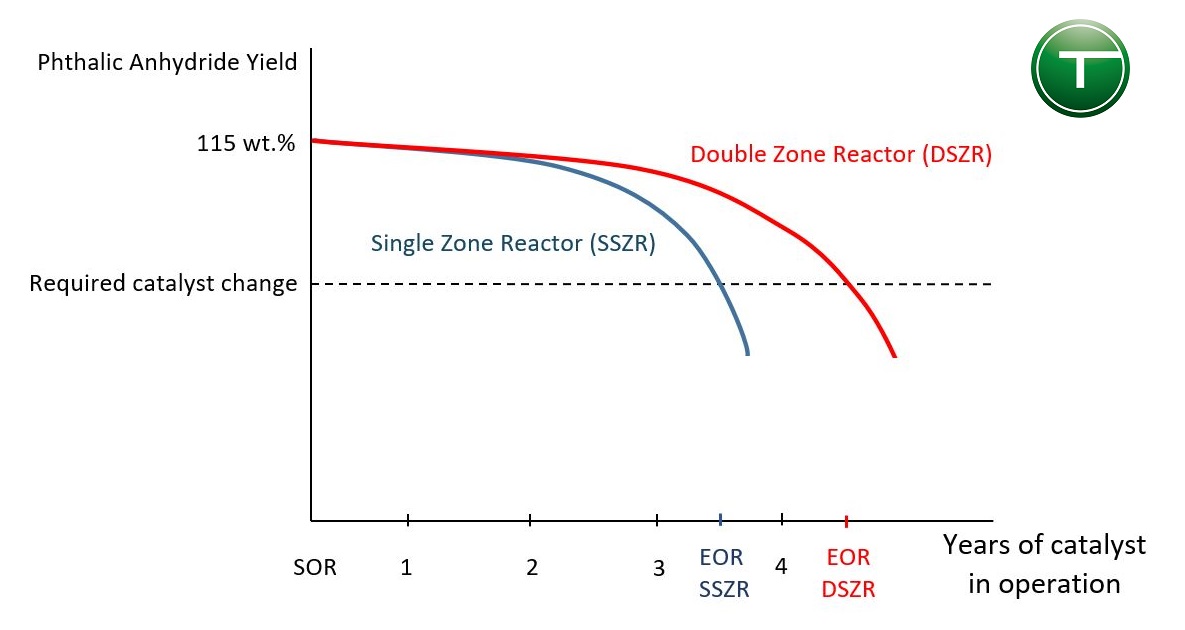

Following the successful market introduction of our Maleic Anhydride Double Salt Zone Reactor (DSZR) with its superior performance compared to Single Zone Reactors, we developed the patented DSZR applicable for the production of Phthalic Anhydride (PA).

The development of a new reactor derives from the needs of catalyst manufacturers facing the challenges of the PA catalyst life cycle due to the multi-layer type of catalyst bed, where catalyst layers require different operating temperatures for their optimal performance.

The existing multi-layer PA catalyst operates with the Start-Of-Run salt temperature of about 340 °C, while the reaction yield can reach up to 115 wt.%. During catalyst operation, the salt temperature must be constantly increased to maintain a high conversion rate and thus a yield.

However, after approx. 3.5 years of catalyst in operation, the salt temperature exceeds 350 °C, and a significant negative effect, in terms of performance reduction, is visible mainly on the last catalyst layer, resulting in non-economical production leading to the catalyst change.

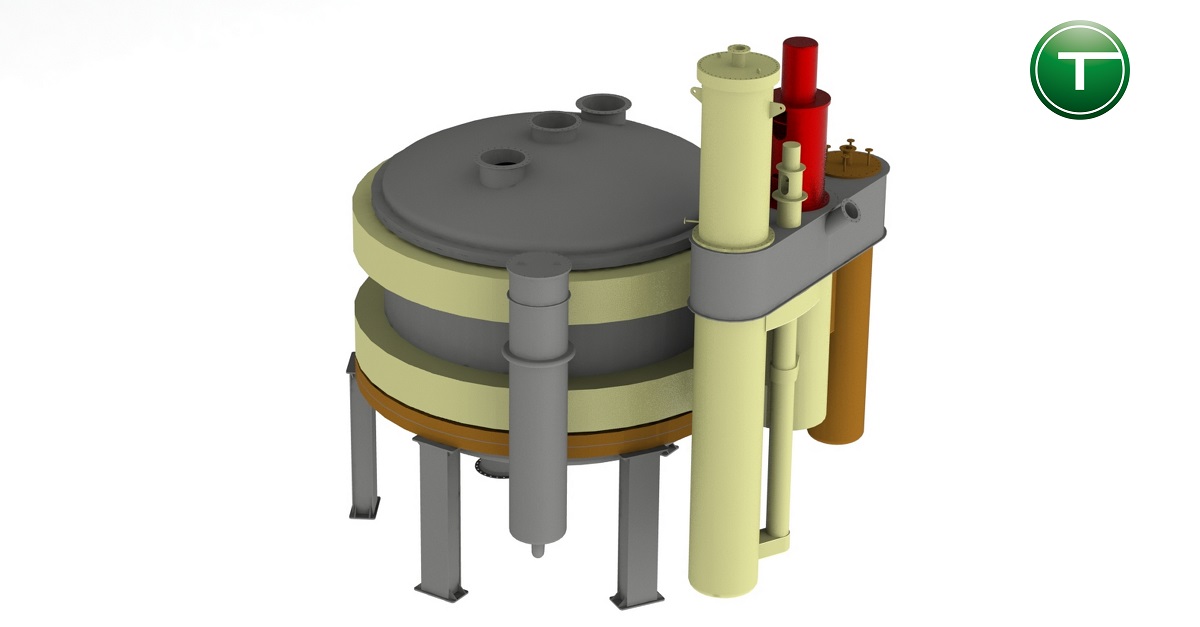

Technobell’s Phthalic Anhydride Double Salt Zone Reactor offers a complete solution where the main reaction zone temperature increases over time according to the reaction performance with the aim of maintaining the highest reaction yield, and the bottom reactor zone temperature is maintained at the optimal level for the last catalyst layer, which is only possible in Double Salt Zone Reactor due to its unique ability of separately controlled salt temperatures in the two zones.

The positive effect is shown in the guaranteed significant catalyst lifecycle extension, as the last catalyst layer performance reduction is much slower, resulting in a reduction of reactor OPEX.