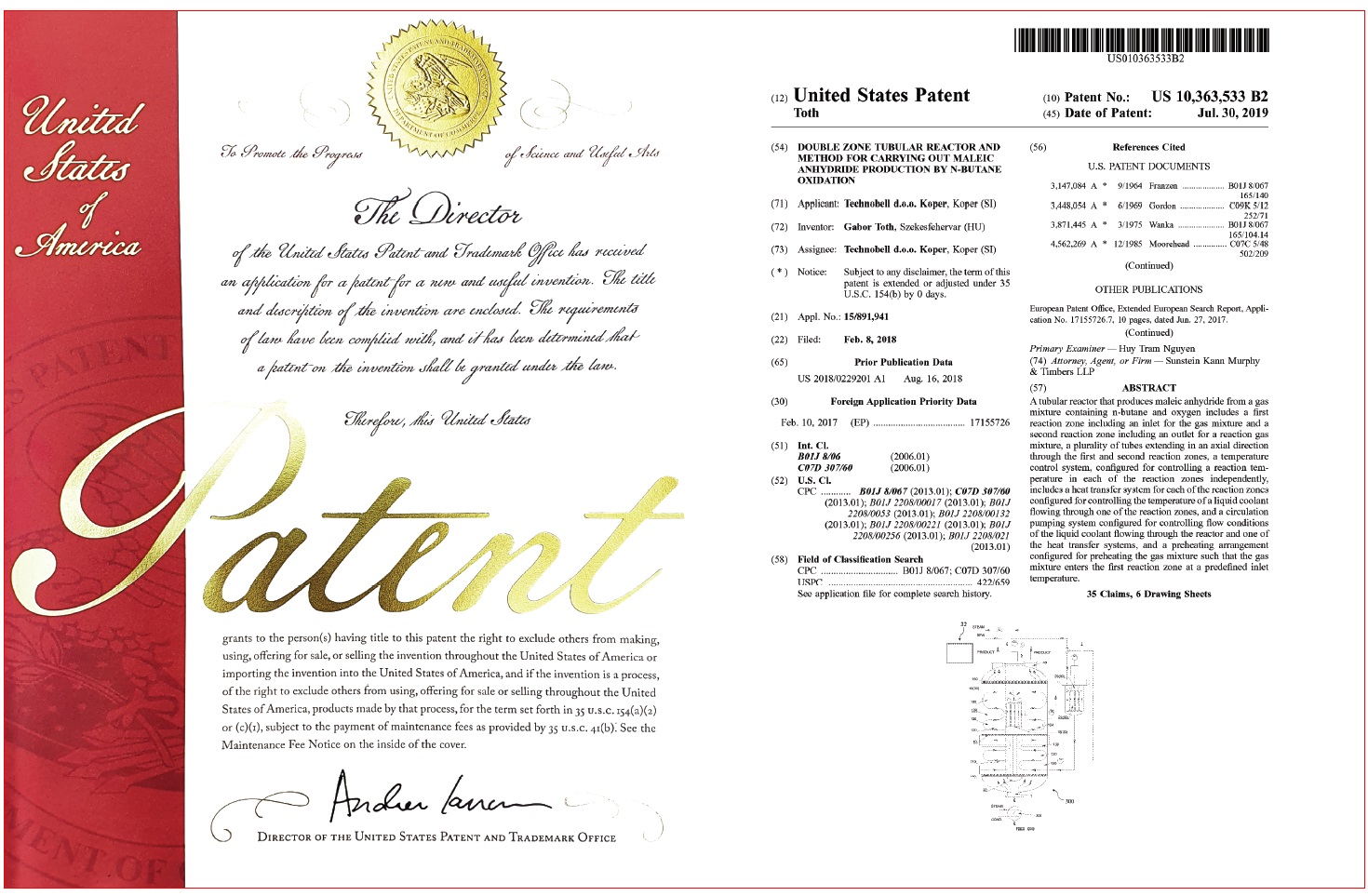

Technobell Technology was granted a patent for “Double zone tubular reactor and method for carrying out maleic anhydride production by n-butane oxidation”

Technobell Technology is proud to announce that we have been granted a patent by the US Patent & Trademark Office for “Double Zone Tubular Reactor and Method for Carrying Out Maleic Anhydride Production by N-Butane Oxidation”. This highlights the innovations that are being carried out in our petrochemical department. We would like to thank our colleague COO Gabor Toth, the inventor, and his team who are focused on constant process and equipment design developments.

On this occasion Gabor Toth said: “Receiving this Patent is not only a validation of our know-how but even more confirmation from a world-renowned independent institution about the value of our R&D activities that result in new and useful innovations. We believe that by the application of Technobell’s exclusive State-of-the Art Maleic Anhydride Technology and Double Zone Reactor, our clients will be satisfied owner of the market leading production performance.”

Abstract from the patent “Double zone tubular reactor and method for carrying out maleic anhydride production by n-butane oxidation”

A tubular reactor that produces maleic anhydride from a gas mixture containing n-butane and oxygen includes a first reaction zone including an inlet for the gas mixture and a second reaction zone including an outlet for a reaction gas mixture, a plurality of tubes extending in an axial direction through the first and second reaction zones, a temperature control system, configured for controlling a reaction temperature in each of the reaction zones independently, includes a heat transfer system for each of the reaction zones configured for controlling the temperature of a liquid coolant flowing through one of the reaction zones, and a circulation pumping system configured for controlling flow conditions of the liquid coolant flowing through the reactor and one of the heat transfer systems, and a preheating arrangement configured for preheating the gas mixture such that the gas mixture enters the first reaction zone at a predefined inlet temperature.